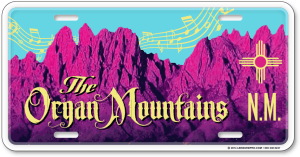

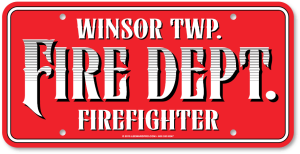

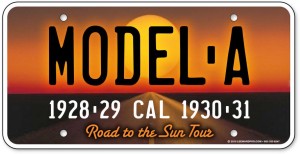

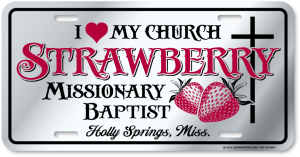

Tag Design Portfolio

Featured below are car tags I’ve designed for Leeward Productions, my business that sells custom promotional license plates. Some of the designs show either “before/after” examples — what the customer submitted vs. the finished plate I created for them — or alternate design options, as indicated by the bright green labels in the lower tag corners. (Click/tap to enlarge and all will be revealed.)

next page: The Design Process →The Design Process

Keeping it simple

I am primarily a typographer and layout artist when it comes to graphic design: I have no illustration skills to speak of. I do vectorize a lot of artwork — which means rebuilding logos or illustrations in Adobe Illustrator by hand-tracing the low-resolution bitmap artwork I typically receive from customers for their license plates. But that’s a technical skill, not the actual creation of artwork from scratch.

If customers have artwork or a logo to contribute, I work with that, otherwise I select clip art from online sources or my own library. Additionally, the cost of design work is rolled into the pricing of plates at Leeward Productions rather than priced separately, so customers don’t have to worry about it. The allowance is relatively modest, though, so as to maintain competitive prices.

The “Zen” of creating artwork for screen-printing

Another requirement, or perhaps limitation, of the design process has to do with the fact that most license plates are screen-printed. There are a couple of reasons for this. The first is that it’s still a less expensive way to print many promotional-product items than more recent digital methods. Secondly, screen-printing remains the “gold standard” for outdoor durability when it comes to colorfastness outside in sunlight, as well as imperviousness to inclement weather and “on the road” conditions.

The tradeoff is screen-printing normally uses single, individual spot colors as opposed to the full color spectrum — in many cases just one or two ink colors. Complex or “Photoshop” artwork that requires the use of full-color is usually not possible with screen-printed license plates, so simpler art that looks good and projects well at a distance with a single ink or two is preferred. There is a side benefit to this: artwork using one or two ink colors needs to be “high-contrast” for good visibility at a distance, which often increases the graphic impact, all other things being equal. This is an underappreciated “plus” to using fewer colors in graphic design, if handled well.

Simple can be beautiful

All of this means that complex designs are usually avoided in my work with license plates, and so I focus on classic design/layout principles featuring typography, my forte. Which is a good fit with the requirements of car tags, where the message is communicated by a few large words and a quickly recognizable graphic laid out in appealing fashion.

next: Business Overview →Business Overview

How things began

The company that eventually became Leeward Productions was started in 1989 by my long-time friend, artist Lee Shiney. We had initially gotten acquainted a few years prior to that when he needed typesetting work done and had heard via word of mouth about the freelance phototypesetting business I ran at that time.

In those days Lee’s business was called Shiney Communications, and he was doing freelance graphic design along with advertising creative, then came up with the idea to design and sell license plates to churches for use as an outreach tool. Also making up a part of the business were Kansas-themed tags Lee designed for resale in gift shops statewide. (I have seen a few of these tags still on the road after 20+ years.) For some years Lee ran the operation by himself, assisted by his son and daughter from time to time when needed.

In 2002, Lee was slowly recovering from (successful) cancer treatment about the time that my stint working at an ad agency had come to an end. I was trying to figure out what to do next, Lee said he could use help with the business, and so we decided to partner together and see where we could take things.

Lee + Ward = Leeward Productions

By 2003, after renaming the business Leeward Productions (combining our first names to reflect our arrangement), we got things going and split up the duties. Lee handled the “back end,” that is, printing, production, and shipping of plates, while I dealt with the “front end” — calls and email from customers, the administrative work, plate design, and the creation and maintenance of a website to take the business online. (To that point, Lee had generated sales mostly with postcard promotions, which we also tried a couple of times together as well, but response rates were no longer as successful as they had once been.)

Sales began ramping up significantly late in 2004 once I got a Google AdWords campaign going, which contributed about half our website traffic. Just prior to that, I spent most of the summer of 2004 programming a FileMaker Pro database to be able to handle the anticipated increase in volume and streamline our job tracking and other internal administrative tasks.

Lee eventually moves on

From that point we had steady sales through mid-2008, when Lee decided to move on from the business. Back trouble was starting to become a serious issue for him, even with the semi-automated screen-printing press we had invested in, and also, pursuing fine arts had been a long-term career goal he had yet to fulfill — so it seemed like a good time to move on and get serious about that. (See Lee’s fine arts work at his websites LeeShiney.com and Arcadia Art Factory.)

I looked briefly into the idea of finding another individual to take over Lee’s side of the business, but since the other friends I knew were otherwise involved, and personal trust is such a large issue in tight partnership arrangements like Lee and I had had, I decided to shut the business down, at least temporarily, while I explored what else I might do.

A year’s hiatus — plus a little lawn-mowing for the soul

While doing some freelance design work that came along at the right time to keep the bills paid, I went out to the career placement office at Wichita State, where I’d gotten my business degree, to explore options. I took the standard psychological/personality profile tests including Myers-Briggs, looked at potential career options, attended an end-of-semester job fair, and so forth.

(Aside: To shore up the budget, I also got a temporary business going mowing lawns for several people in our neighborhood plus a few others in the immediate vicinity. Surprise… or maybe it shouldn’t have been, given my physical-fitness streak: I enjoyed the physical labor, felt better, and my mental outlook and mood improved when not sitting behind the computer so much. It also got me started on “bodyweight” training — pushups, pull-ups, etc. — to improve my arm strength to deal with all the weed-eating work required.)

In the meantime, a few people who knew of my situation had been asking why I didn’t just keep going with Leeward Productions but subcontract out the plate production. The main reason I hadn’t done so was I assumed the profit margins would not be as good. While they had never been as good as Lee and I had hoped, I assumed with outside companies doing the production, they would be lower yet unless the business were significantly expanded to hire hourly workers and scale things up, which I wasn’t interested in.

However, after things at the career placement office had not panned out, I decided to look into starting up Leeward Productions again, and it turned out that profit margins were actually better, significantly better, if — and this was a big if — one found the right producers to work with. I eventually discovered that the key was getting hooked up with the promotional product industry’s network of suppliers, where there is an agreement that distributors (which is what Leeward Productions would be) handle only sales to end customers, and the suppliers handle only production/manufacturing with no poaching of end customers from distributors.

With this arrangement, suppliers/producers focus exclusively on manufacturing to get their production costs down as far as possible for distributors. And distributors can jettison any need for equipment overhead so they can do what they do best and focus on end-customer sales. (Note: There has been some breakdown in this “gentleman’s agreement” type of contract in recent years, which has been a source of controversy in the industry.)

Relaunching the business

So I decided to jump back in with Leeward Productions again. But successfully working with outside suppliers meant that I would have to add a completely new module to the FileMaker Pro order-tracking database I’d previously created, in order to be able to efficiently and accurately send orders to outside suppliers. The database had been a one-trick pony before in terms of the production detail that needed to go to Lee, and not only that, it was very stripped-down in format.

I spent, I believe, almost a month and a half solid, over Christmas break in 2009 on through the end of January 2010 programming several new tables inside the database to handle supplier costs plus all the other data for easily transmitting purchase orders to the producers I was working with. It was very important that it be programmed meticulously, too, because all it takes is one error in job specifications for a customer’s order to be printed in error. And then if they aren’t amenable to accepting a discounted price, you might have to pay for it to be completely reprinted at your own expense, eating up any profit there might have been, sending you far into the red on the job. (I like to say that the great thing about a database is it’s like an elephant — it never forgets. Which is good, but on the other hand, it means you also have to be careful when inputting data that it’s correct as well, or you can still lose your shirt on an order.)

Once I got the newly expanded, outside-supplier-aware database module programmed, and found the best suppliers to work with — which was also a challenge in itself — Leeward Productions was back in business, and I’ve been running it on that basis since.

Website traffic = guaranteed sales, but therein lies the rub

The one remaining significant issue is that in the years since I first launched the company’s Google AdWords campaign, the entire AdWords model as a business proposition has become more and more (and yet more) complex to run and get successful results with. While in the early years, say 2004 to 2008, we were frequently getting anywhere from 5% to 15% click-through rates (much higher than average, as I had done a lot of research and gone to considerable lengths with the implementation), they have dwindled far below that level since.

Due to added competition but particularly larger players moving into almost every conceivable AdWords advertising niche, what used to be a place where the little guy could compete on a level playing field with the big corporations (the initial “promise” of AdWords) is no longer true. Not unless I were to hire someone at least part-time internally to take care of it, or start paying big bucks to outside search-engine marketing firms (and the field is notoriously full of sharks), neither of which I am inclined to do. And even then there are no guarantees, with the gradual downward trends in AdWords ROI (return on investment) these days due to increasing saturation of the pay-per-click market.

So, I decided not to “push the river,” and instead to diversify away from making my income too heavily dependent on car tags. The LeewardPro.com website works well at garnering sales proportionally to the traffic it gets, and I’m finding I enjoy things at the current level. At this point, with the infrastructure for the business having finally been built out about as well as needed, I am getting a decent return on my time invested, based on the “organic” search traffic the site receives.

It turns out I am enjoying it more as a part-time business anyway, when it isn’t so all-consuming. Variety is the spice of life, and that is one of the benefits of self-employment. Unlike the regular job market, it doesn’t have to be “all or nothing” (although it certainly can be), and you can diversify with more than one income stream. That’s the way I prefer things at least, especially in today’s dicey economy.

Wrap-up

In summary, then, currently Leeward Productions is a one-man operation — I handle all customer dealings, maintain the company website, design customers’ plates, and then get them produced through national wholesale producers who work exclusively with promotional product distributors like myself.

Note: There are 20 states that issue official license plates for the rear of vehicles only, leaving the front plate open for other use by consumers and businesses. These states are: Alabama, Arizona, Arkansas, Delaware, Florida, Georgia, Indiana, Kansas, Kentucky, Louisiana, Michigan, Mississippi, New Mexico, North Carolina, Ohio, Oklahoma, Pennsylvania, South Carolina, Tennessee, West Virginia.

For more information, or to get started ordering license plates for your group, see the Leeward Productions website.

← return to: Tag Design Portfolio